★ DAVOS-KLOSTERS, SWITZERLAND ★ World Economic Forum Annual Meeting ★ 19–23 January 2026

★ DAVOS-KLOSTERS, SWITZERLAND ★ World Economic Forum Annual Meeting ★ 19–23 January 2026

ClearWater Shipping BV

Day 03 ::: World Economic Forum 2026 in Davos, Switzerland

Dio van der Stel meeting Belgium Prime Minister Mr. Bart Albert Liliane De Wever, opening the session on: Trade Lanes tomorrow - Greening the Maritime Sector

#davos26 #Clearwatershipping #dpworld #greenshipping #blueocean #MaritimeExcellence #OperationalCredibility #GreenShipyard #100Years #ProvenOperations #InfrastructureInvestment #MarineInfrastructure #GreenShipping #ClimateInfrastructure #Davos #Davos2026 #BlueEconomy #SystemsThinking #WorldEconomicForum #WorldWomamDavosAgenda2026 #WEF26 #BrandSA #clearwatershipping #capeglobalgroup

Cape Global is a proud participant in Davos 2026, World Economic Forum Annual Meeting and Collaboration for the Intelligent Age. Davos brings together global leaders to tackle challenges in geopolitical shifts, economic growth, AI, and climate action through dialogue, innovation, and public-private partnerships.

Green Projects by Cape Global

Cape Global has strong alignment and deep commitment to a green future in all world landscapes and oceans.

Our current Green Projects are focused intensively on shaping tomorrow with smart Biotech: Saldanha Bay Green Shipyard Bioremediation & Environmental Restoration Programme.

Saldanha Bay Green Shipyard Bioremediation & Environmental Restoration Programme

Project Summary

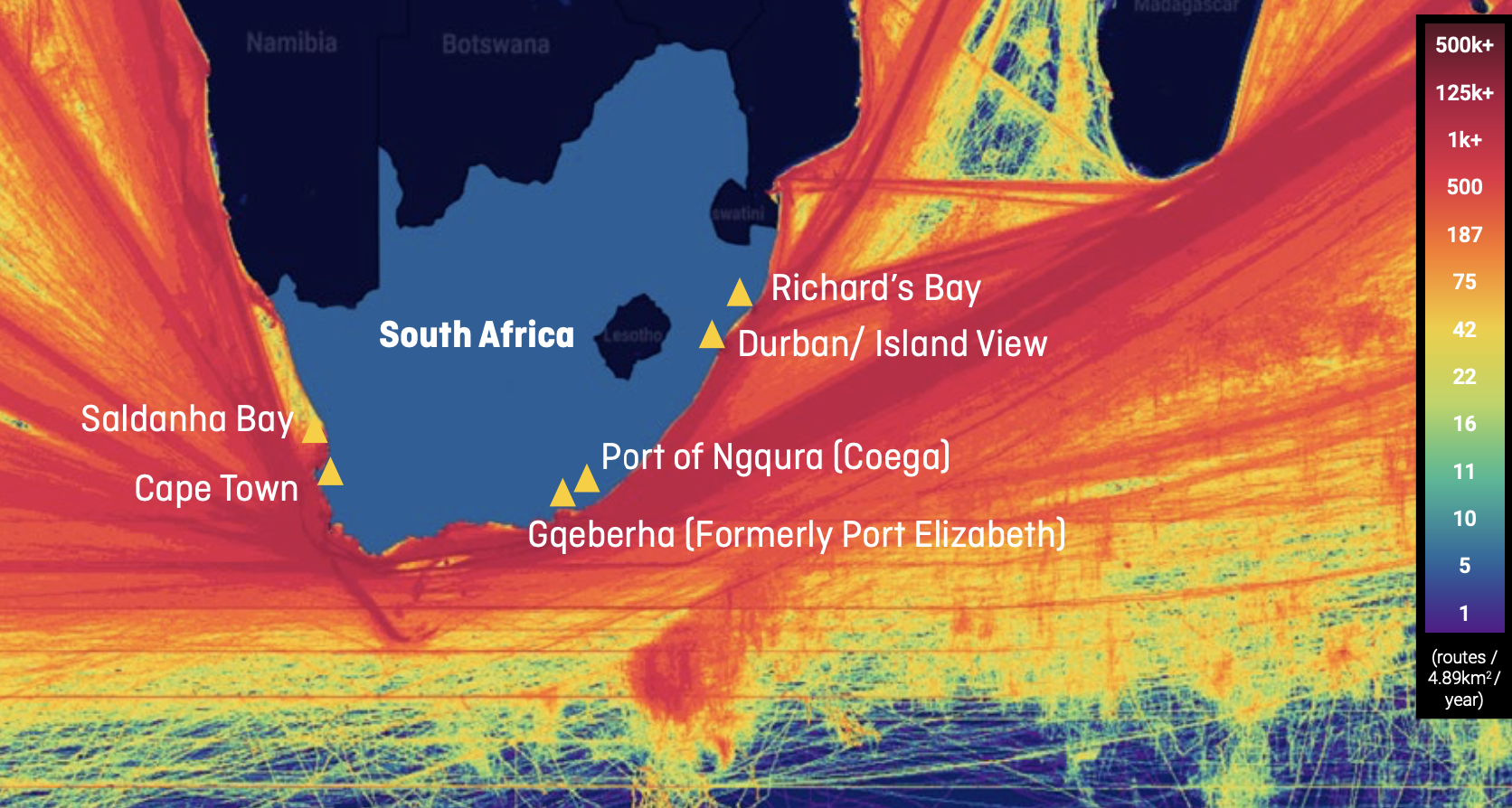

Boer Shipyards has secured rights to establish a world-class shipyard and floating dry-dock complex in Saldanha Bay, South Africa’s deepest natural harbour and a strategic naval, commercial, and industrial marine hub.

To achieve Green Shipyard Certification and to support the Dutch government’s global sustainability agenda, Boer Shipyards proposes to implement the Saldanha Bay Green Shipyard Bioremediation Programme, delivered by EcoZyme (ECZ) in collaboration with South African academic, industrial, and governmental partners.

The project will restore heavily contaminated harbour waters and sediments using a hybrid remediation model combining:

• Advanced microbial bioremediation technologies (ECZ proprietary consortia)

• Mechanical surface cleaning

• Sediment rehabilitation & metal immobilisation

• Microplastic capture systems

• Low-energy aeration & hydrodynamic circulation

• A marine digital twin monitoring system for real-time environmental auditing

This programme will create a fully traceable, measurable improvement in marine ecological health, enabling Boer Shipyards to operate the first certified green shipyard in Africa, aligned with the Dutch Green Maritime Strategy, EU Green Deal, and Mission Ocean frameworks.

CONTEXT & PROBLEM STATEMENT

Overview of Environmental Conditions in Saldanha Bay

Multiple scientific studies (CSIR, SAMSA, UWC Ocean Sciences) indicate that Saldanha Bay suffers from:

Hydrocarbon contamination

Diesel, lubricants, bunker fuel, PAHs

Chronic oil film accumulation in low-circulation basins

Heavy metals in water & sediment

Copper, zinc, chromium, lead, cadmium, mercury

Strongly bound to fine sediment fractions

Organic and nutrient overloading

COD/BOD elevated

Localized eutrophication & algal blooms

Pathogenic contamination

• Faecal coliforms from stormwater & wastewater inflows

Microplastics & industrial debris

• High microplastic density undermines harbour ecology

Degraded sediment layers

• Areas with >1 m contaminated sediment

• Anaerobic, sulphide-rich (“black sludge”) zones

Implications for Shipyard Development

Without remediation:

• Green Shipyard Certification is not achievable

• Long-term liabilities increase (environmental compliance, dredging)

• Operational restrictions may be imposed

• Ecological damage risks reputational harm

• Dutch government cooperation & co-funding opportunities diminish

Therefore, a robust environmental restoration plan is required prior to shipyard commissioning.

PROJECT OBJECTIVES

Primary Objective

To restore the ecological, chemical, and operational health of Saldanha Bay through a scientifically robust, measurable marine bioremediation programme, enabling Boer Shipyards to achieve full Green Shipyard Certification.

Specific Objectives

• Reduce hydrocarbon concentrations by 60–90% across water and surface sediment.

• Lower COD/BOD levels by 40–70% through microbial oxidation.

• Stabilize and immobilize heavy metals in sediment using hybrid techniques.

• Remove 30–50% of legacy microplastics using engineered capture systems.

• Improve dissolved oxygen (DO) levels by 20–40% through hydrodynamic circulation.

• Establish a digital twin monitoring network for continuous data capture, verification, and reporting.

• Achieve independently audited ecological improvement meeting Green Shipyard Certification criteria.

PROJECT PARTNERS

Lead Applicant (Netherlands)

Boer Shipyards Pty Ltd

• Lead investor, shipyard developer

• Drives ESG compliance and certification

• Oversees integration into shipyard operations

Technical Lead (UK | South Africa)

EcoZyme (ECZ)

• Supplier of microbial bioremediation technology

• Developer of monitoring architecture and digital twin

• Lead implementer of bioremediation programme

Key Strategic Partners (South Africa)

• Transnet National Ports Authority (TNPA) – permissions & integration

• CSIR Coastal Systems Unit – verification & sediment mapping

• University of Cape Town – Oceanography Department – marine ecology

• Stellenbosch University Microbiology – lab analysis & QA

• Department of Forestry, Fisheries & Environment (DFFE) – policy alignment

• Saldanha Municipality – local integration & stakeholder engagement

PROJECT DESIGN & TECHNICAL APPROACH

Four-Phase Implementation Plan

PHASE 1

— Baseline Assessment (0–3 months)

Activities:

• Sediment coring & contaminant mapping

• Hydrocarbon fingerprinting

• Metal speciation analysis

• Microplastics density survey

• Water quality profiling (DO, pH, turbidity, nutrients)

• Installation of the Digital Twin sensor network

Outputs:

• Complete environmental baseline

• Real-time monitoring dashboards

• Hotspot identification map

PHASE 2

— Microbial Bioremediation Deployment (Months 3–24)

Activities:

• ECZ bacterial dosing via vessels

• Installation of slow-release Gel Blocks on seabed

• Sediment oxygenation treatment

• Weekly microbial activity tracking

• Hydrocarbon, COD/BOD, sulphide removal

Outputs:

• Significant reduction in hydrocarbons & organic pollutants

• Measurable water quality improvement

PHASE 3

— Hybrid Remediation Measures (Months 6–36)

Activities:

• Targeted metal immobilization (activated carbon & phosphate binders)

• Microplastic capture & removal systems

• Oil skimmers & mechanical debris collection

• Low energy aeration/circulation units (SolarBee-type or SA-built)

• Targeted micro-dredging of hotspots (only if essential)

Outputs:

• Removal or neutralization of non-biodegradable contaminants

• Sediment stabilization

• Full compliance with green-port ecological standards

PHASE 4

— Long-Term Monitoring, Reporting & Certification (Years 2–4)

Activities:

• Continuous Digital Twin monitoring

• Third-party ecological audits

• Independent laboratory validation

• Certification preparation & submission

Outputs:

• Full Green Shipyard Certification

• Dutch & EU compliance documentation

• Ongoing maintenance programme

EXPECTED OUTCOMES

Environmental Outcomes

• Major reduction in hydrocarbon pollution

• Improved dissolved oxygen and water clarity

• Stabilized sediments and lower toxicity index

• Enhanced marine biodiversity recovery

• Long-term ecological resilience

Economic & Social Outcomes

• Supports establishment of Africa’s first Green Shipyard

• Reduces future environmental liabilities

• Creates local employment in SA during implementation

• Strengthens Dutch–South African industrial cooperation

• Models scalable green-port remediation for global replication

Innovation Outcomes

• Demonstrates large-scale microbial marine bioremediation

• Deploys a digitally monitored, real-time marine Digital Twin

• Enhances Dutch leadership in green maritime innovation

Project includes:

• Fieldwork, boats, equipment

• Bacterial supply & distribution

• Sensors, IoT architecture, digital twin model

• Sediment remediation materials

• Personnel, monitoring, audits

• Certification costs

ALIGNMENT WITH DUTCH GOVERNMENT PRIORITIES

This project directly supports:

Dutch Maritime Masterplan

Zero-impact shipyard operations

Clean working harbours

Innovation-driven sustainability

Netherlands Mission-Driven Innovation Policy

• Water quality improvement

• Circular and bio-based solutions

• Emissions and ecological footprint reduction

Dutch–South African Bilateral Cooperation Goals

• Knowledge transfer & skills development

• Joint innovation & industrial collaboration

• Support for climate and environmental resilience

• EU Green Deal & Mission Ocean Objectives

• Restoring marine ecosystems

• Reducing pollution in key blue economy zones

• Technology-driven environmental stewardship

RISK MANAGEMENT

Risk

Mitigation

Regulatory delays

Early engagement with TNPA, DFFE, SAMSA

Severe contamination hotspots

Targeted micro-dredging & chemical immobilisation

Weather disruptions

Staggered work windows & extended project horizon

Stakeholder conflict

Formal engagement programme and transparent reporting

Technical monitoring failures

Redundant sensors + cloud backup + manual QA

SUSTAINABILITY & LEGACY

This project establishes a fully operational:

• Green Shipyard Environmental Management System (EMS)

• Real-time Digital Twin for marine quality

• Ongoing ECZ bioremediation maintenance programme

• Permanent microplastic & debris capture operation

Long-term benefits include:

• Reduced operational costs

• Lower dredging demands

• Uninterrupted compliance with international standards

• Strong ESG positioning for Boer Shipyards globally

REQUEST FOR SUPPORT

Boer Shipyards and EcoZyme hereby request Dutch co-financing to:

• Undertake essential environmental restoration

• Install next-generation green port technologies

• Enable the creation of Africa’s first Dutch-supported Green Shipyard

• Deliver measurable environmental improvements with full transparency

• Strengthen the Netherlands’ leadership in maritime sustainability worldwide

REQUEST FOR SUPPORT

Boer Shipyards and EcoZyme hereby request Dutch co-financing to:

• Undertake essential environmental restoration

• Install next-generation green port technologies

• Enable the creation of Africa’s first Dutch-supported Green Shipyard

• Deliver measurable environmental improvements with full transparency

• Strengthen the Netherlands’ leadership in maritime sustainability worldwide